Pattern Dependency Inspection Sheet for 669929661, 7136375603, 912901292, 5592451007, 8662137456, 2102393234

The Pattern Dependency Inspection Sheet serves as a pivotal instrument in enhancing quality assurance within manufacturing operations. By examining the interrelationships among unique identifiers such as 669929661 and 7136375603, it fosters a deeper understanding of product performance. This structured approach not only aids in monitoring and traceability but also highlights areas for potential improvement. As the analysis unfolds, the implications for operational efficiency and product quality become increasingly evident. What insights might emerge from this systematic examination?

Importance of Quality Assurance in Manufacturing

Although quality assurance (QA) may often be viewed as a procedural formality, its significance in manufacturing cannot be overstated.

Effective quality control mechanisms ensure compliance with established manufacturing standards, fostering consistency and reliability in production outputs.

Overview of the Pattern Dependency Inspection Sheet

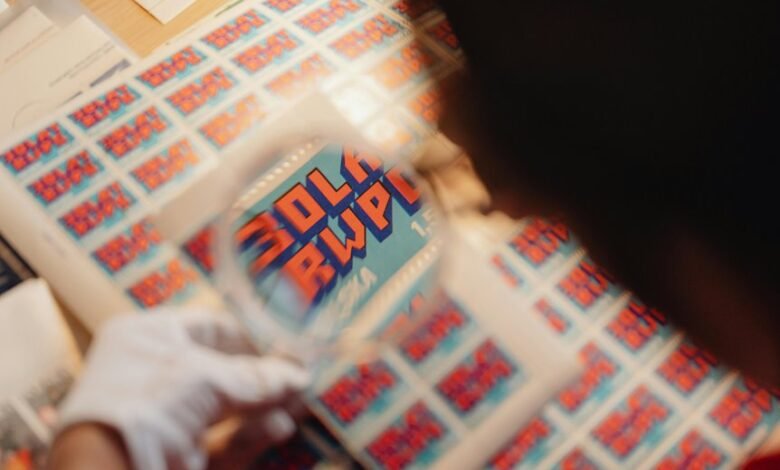

When evaluating manufacturing processes, the Pattern Dependency Inspection Sheet serves as a critical tool for identifying and analyzing interdependencies among various production patterns.

It enhances pattern recognition capabilities, facilitating informed decision-making. Additionally, the sheet supports data validation by ensuring that all relevant information is accurately captured and assessed, ultimately contributing to improved operational efficiency and the reduction of errors in production workflows.

Analyzing Product Performance With Unique Identifiers

The incorporation of unique identifiers in product performance analysis significantly enhances the ability to track and evaluate individual items throughout the manufacturing process.

Benefits of Implementing the Inspection Sheet in Operations

Implementing an inspection sheet within operational processes offers numerous advantages that directly contribute to enhanced efficiency and product quality.

This tool facilitates process optimization by identifying bottlenecks and ensuring compliance with standards. Additionally, it enhances operational efficiency by streamlining workflows and reducing errors.

Consequently, organizations can achieve greater reliability in their outputs, ultimately fostering a culture of continuous improvement and accountability.

Conclusion

In the landscape of manufacturing, the Pattern Dependency Inspection Sheet acts as a lighthouse guiding ships through foggy waters. By illuminating the interdependencies among unique identifiers, it ensures that each product is meticulously monitored and traced. This structured approach not only enhances operational efficiency but also fosters a culture of continuous improvement. Just as a lighthouse prevents ships from veering off course, this inspection sheet safeguards quality, ultimately steering the production process towards excellence and reliability.